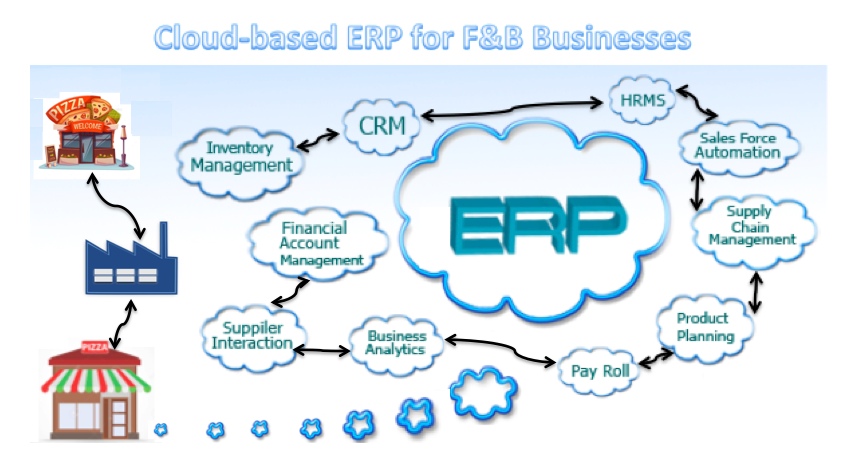

Within the Food & Beverage industry, there are a range of recent trends that add complexity to the way companies function. Starting from food safety to the regulatory acts, restaurant owners and food manufacturers are under more pressure than before. One of the best ways to handle the growing complexity of this industry is to invest in efficient technologies such as an ERP system. A well-designed ERP system can put together all of these aspects into a single set of information, facilitating the company’s management. Apart from improving the operational performance, it also aids to incorporate all the compliance rules into one place making sure that they are being fulfilled.

In order to choose the right ERP system for a food and beverage industry, the software must have all the functional requirements which are required for the organization. This is very much true especially in the food and beverage industry due to its highly complex functional nature. Below are few aspects, a food and beverage industry ERP system must have to be fully functional.

Regulatory Compliance: This aspect is no greater aspect than that of regulatory control. The need for raw material isolation, traceability, environmental guidelines and regulatory compliance must be achieved at the highest level. The system must be agile, thorough and rapid if the product recalls occur. Additionally, the regulations are becoming more exact and constantly changing.

Quality and supply chain management: The ability to control production quality is crucial. F & B industry ERP systems must have the capability to record real-time data on various aspects of supply and manufacturing during production and store the data for future reference.

Inventory management: Iin F & B industry, excess inventory is more than just wasted cost. For example, when perishable raw materials are involved, delays in processing and surplus inventory may lead to safety and quality issue. This is why inventory optimization is a ‘must-have’ ERP feature for F & B industry.

The ERP system must have materials requirements planning (MRP) functionality and traceability features, thus enabling to plan ‘Just-in-time’ delivery of raw materials or ingredients.

Single source system: The system must allow to trace costs associated with certain products and product lines down to the ingredients used in their products. Alternatively, a single system has to be implemented in order to manage production, financials, quality, production, inventory and many more.

Importance of choosing a food and beverage specific ERP

It is important that the ERP system you choose can answer to several issues you face. By obtaining the right ERP system specific to F & B industry, you will be proficient in meeting industry demands (operation-specific) by alternatively increasing your profits, satisfying customers and ultimately improving productivity.

While the below listed are few functions that F & B industry needs in an effective solution.

Flexible and Extensive Lot Control

Code Tracking

Materials Tracing

Regulation Management

FDA Requirements

Storage and Handling

Packaging and Labeling

Recall Management

Test/Mock Recalls

Recall Data Organization

Expiration Date Monitoring

Warning Notices

Inventory Rotation Management

Waste Tracking

Growth Capabilities

Addition of Processes

Additional User Support

ERP solutions can be an outstanding tool that do boost your business profits, but it is important to remember that without the right ERP, the benefits it reap begin to lessen rapidly. An ERP system is a wise choice in this ever changing and complex field.